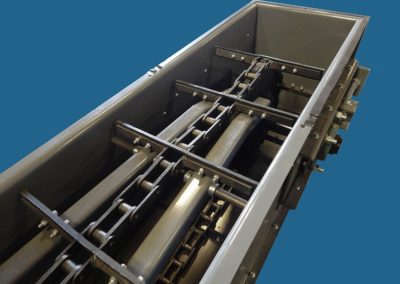

Conveyors

Chief horizontal chain conveyors come standard with fully galvanized intermediate sections and can be customized to your application by combining exterior gauging, liners, chain types, sprocket options, paddles and speed requirements. By using components fabricated to exacting specifications, your Chief chain conveyor will be easy to assemble and provide long-lasting service.

What Makes Chief Better

Bolt-on panel

Panel easily removes to allow lifting out the shaft for easy maintenance

Bolt Connections on intermediate seams

Intermediate seams have bolt connections with staggered bottoms to provide secure joint without need for welding

Telescoping-type take-up system

System uses a simple threaded rod for easy adjustment and secure locking

Broad-throat opening

Broad-throat opening between the start of the discharge and the sprocket allows for unobstructed discharge

Shipped with Covers

All conveyors shipped with required covers

Carry back cups

Reversing conveyors available with carry back cups for full conveyor clean out

Idler and Rail return systems

Idler return systems are used for smaller conveyors; rail returns are standard on 21″ (53.34cm) and wider conveyors

Dependable

Dependable chain/sprocket combinations

Incline conveyors

Incline conveyors offer flexibility and reliability